In constant pursuit of delivering cutting-edge environments for our clients, SGA has embarked on an exploratory journey into the use of mass timber as a construction method for research and life sciences development.

As these industries continue to advance, it is important that the spaces supporting their growth evolve in parallel. With the goal to provide an uncompromised facility that exceeds Class A status, SGA has partnered with Thornton Tomasetti, Code Red Consultants, BR+A, Consigli, and a leading life sciences developer to realize the true potential for the first mass timber research development in New England.

With sustainability, resiliency, and construction efficiency at the forefront of our aspirations, this team has conceptualized a mass timber building that provides flexibility to empower world class research while prioritizing the human experience. This mass timber concept is based on industry standard dimensions for laboratory bay spacing, meets the requirements for structural and vibration control, and accommodates complex ventilation systems all while significantly reducing embodied carbon and introducing natural elements to promote wellbeing.

Considering an urban site in one of Boston’s leading life sciences clusters, the project team has proposed two buildings that create an experiential research community for today’s most innovative scientists and their organizations. The first is a nine-story building focused on offering a flexible and efficient research environment. The second is a four-story, hospitality-inspired facility delivering a wide array of on-site amenities that also offers incubator space for start-up and early stage research companies.

Join us for a deep dive into the solutions that prove this innovative market offering is primed for collaborative execution.

LAB + LIFE SCIENCES TODAY

Driving scientific advancement and adding immense value to modern society, lab and life sciences innovation–alongside the spaces that empower it–have become an increasingly public-facing industry. These developments continue to migrate into urban cores and bring with them the dawning of a new age for diverse communities across the globe.

Flexibility in programming, safety, and productivity have created a baseline for the design of these facilities that allows the focus to shift further toward the human experience. This concept strives to continuously elevate the laboratory environment by putting ‘science on display’, giving visibility to the research spaces that have historically been inwardly focused. Additionally, the design seeks to improve the human experience for the scientists completing vital work within. State-of-the-art, sustainable, experiential design positions the organizations who build and occupy these spaces as desirable employers aiming to attract and empower leading workforces.

AN EVER-EVOLVING LANDSCAPE

By nature, the science and technology industry is on the cutting edge of innovation. Therefore, the spaces that facilitate this critical work should be as well. SGA has been passionately involved in the growth and evolution of lab and life sciences design for years; carrying a vision for the future where these buildings enhance the human experience by taking inspiration from hospitality, leveraging biophilic design, and maintaining a strong focus on sustainability. These priorities align with research companies and their unique missions to advance human health.

As we continue to pioneer the future of these developments, three pertinent points drove our exploration: 1. a predominant focus on sustainability and our persistent fight against climate change; 2. increased transparency and placing ‘science on display’ to celebrate the groundbreaking achievements within; and 3. an emphasis placed on elevating the occupant experience to attract and retain top talent.

Through this study, our team has visualized an immediately deployable concept in which mass timber represents the future of research and life sciences development.

SOLUTION-DRIVEN ENDEAVORS

Thought leaders within SGA sought to produce a ready-to-use guide that would illuminate real world applications for the concepts developed here. To do so, designers introduced leading engineers, consultants, and a developer to the table so more comprehensive contributions could be made from all sides of a project team. In the following sections, this group explores important considerations in regard to sustainability and resiliency; structure and programming; applicable code and IBC evolutions; cost and constructability; as well as design aesthetic and flexibility.

SUSTAINABILITY + RESILIENCY

As designers, our responsibility to fight climate change is paramount. This belief permeates throughout our design process, and directly informs the solutions we put forth for our clients. Our passion for achieving breakthroughs in sustainable design drives our work and has allowed SGA to deliver several net-zero lab buildings, most recently including Innovation Square 3 which became the City’s first approved LEED Zero Carbon life sciences building. Introducing mass timber as a tool for lab design allows us to further advance this critical mission.

In addition to significantly reducing the embodied carbon of a building, mass timber improves construction efficiency, offers its carbon sequestering qualities, increases the opportunity for deconstruction at end of life, and contributes to the biophilic elements of a building’s design.

Referring to the greenhouse gas emission associated with the production, transportation, and construction of materials, the majority of a building’s embodied carbon is embedded in the structural system. Thornton Tomasetti highlighted that the decision to use mass timber in the execution of this proposed development would result in a 40% reduction of embodied carbon over a steel structure. In addition to the reduction in embodied carbon in the materials, the construction methodology also calls for smaller crews on site, which equates to lower emissions for construction teams and processes.

While the production of steel and concrete accounts for 15% of worldwide greenhouse gas emissions, the use of mass timber provides the opportunity for a significant reduction by eliminating these materials from a building’s structure. Alongside the avoided emissions that mass timber provides, it has the advantage of serving as a carbon sink. The carbon stored in the wood over the lifetime of the building, called biogenic carbon, is not included in a standard life cycle assessment but further adds to the carbon advantage of mass timber over alternative materials.

Made viable by the modular elements, standardized dimensions, and reversible metal connections unique to the mass timber system, de-constructability refers to the ease with which a building or structure can be taken apart or dismantled at the end of its useful life. The ability to do so ensures compliance with material circularity, laying out a complete guide for the building’s lifecycle and future. Material Passports, a digital record of each unique material element in a building, help to facilitate circular material strategies at the end of the building’s life that inform material recovery, reuse, and recycling.

STRUCTURAL CONSIDERATIONS + PROGRAMMING

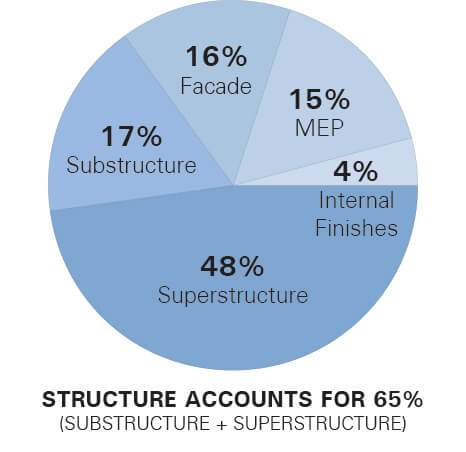

The key to fully unlocking the use of mass timber in laboratory space is retained flexibility in programming. The nature of the work performed in a lab building relies on extensive MEP infrastructure, complex equipment, a robust mechanical penthouse, large-scale loading facilities, and other critical support spaces at the ground level. The upper levels must be organized to offer flexible and efficient zones for research by maintaining necessary dimensional clearances.

The goal of this study is to employ mass timber in a way that supports all of these critical objectives resulting in a state-of-the-art building that outperforms its steel and concrete counterparts. This solution envisions a primary mass timber framing system representing the majority of the building’s structure, with steel being employed only in limited locations to facilitate vertical infrastructure, support critical mechanical equipment, and to provide long-span clearances where needed for internal loading activities.

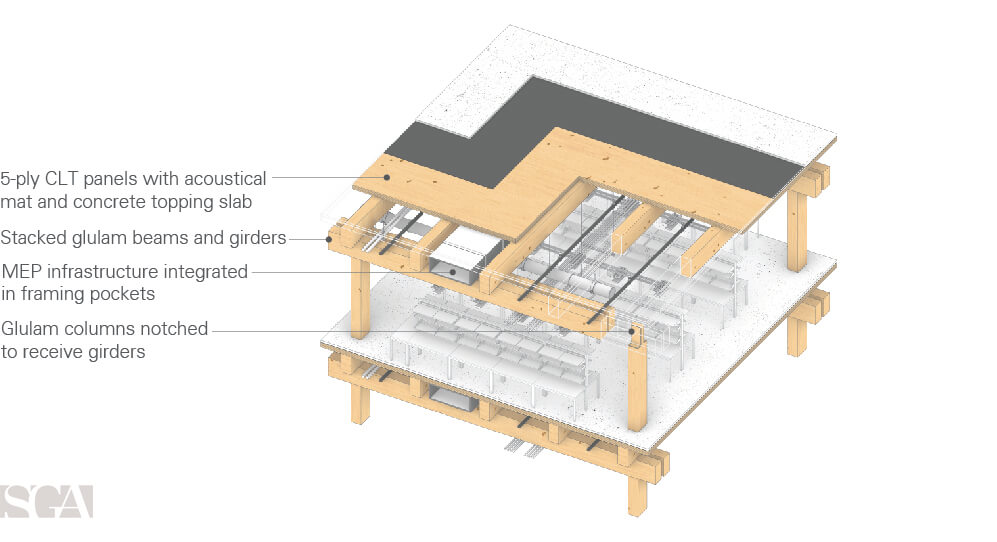

Initially, four structural concepts were compared. While each concept proved viable, a 33′ x 33′ clear span provided the most flexibility for interior programming. The structural framing system consists of stacked beams and girders. A series of 27 ½” deep wood glulam beams are supported by paired 27 ½” wood glulam girders. Columns, spaced 33’ apart, are notched at the top to receive the girders–transferring the floor loading to the foundation.

Organized around a 55’+ core-to-perimeter dimension, an intermediate column is introduced to delineate between potential benching and lab support zones (aligned with lab planning best-practices). The resulting spaces offer the flexibility needed to accommodate a diverse group of tenants with varying scientific processes.

This stacked construction positions beams and girders in opposing directions to create a plenum allowing MEP systems to be woven into the structure. Mechanical ductwork, fire protection systems, piping, and conduit are integrated within these pockets (over the girders) to create a functionally cohesive building.

The structural floor system consists of standard five-ply CLT panels, a ½” acoustical mat, and three inches of concrete topping. This system would replace the conventional concrete on metal deck construction used for a steel framed building. The concrete topping and acoustic mat are designed to minimize sound transfer between floors whereas the concrete topping/acoustical mat and CLT plank will meet or exceed the standard vibration criteria of 8,000 mips.

CODE CONSTRAINTS + EVOLUTIONS

In recent years, the International Building Code has made great strides in respecting the use of mass timber as a viable construction method for a wide range of use cases and scenarios. Based on these code advancements, SGA has employed mass timber for projects like 90 Arboretum Drive, the first fully framed mass timber office building to be constructed in New England. With the anticipated release of IBC 2024, SGA expects to see continued improvements that highlight the path forward to exposing all timber, showcasing the beauty of this natural material throughout a building’s entirety.

Related to fire protection, mass timber buildings can comply with code requirements without the use of additional fire-resistant materials. Fire protection is inherent in the mass timber product; the thickness of the beams/girders allow outer layers to char while remaining structurally sound. Reducing the negative impact of a potential fire, and performing similarly to steel with applied fireproofing.

Partnering with a knowledgeable team who is skilled in the navigation of these codes enables a development team to continuously push the use of forward-thinking methods and materials. On these grounds, SGA and Code Red Consultants have identified a path forward for exposing 100% of the mass timber in both buildings.

COST + TIMELINE

There are a variety of points to weigh when reviewing the cost and timeline of constructing a mass timber building. While the prefabricated product might come at a premium, the timeline for delivery and size of your onsite construction team are decreased. The mass timber system is designed for simple structural connections to allow for increased speed and decreased complexity of construction. Mass timber also provides efficiencies in interior work as designers frequently leverage exposed timber as the final finish for columns and ceilings; reducing the cost and timeframe for the installation of other finish materials. It is important to consider that the value of sustainable development cannot be measured exclusively by its price.

As the mass timber product continues to work its way toward total viability across a broad array of commercial executions, we expect to see reductions in cost due to an increase in demand as sustainable production methods scale in response.

DESIGN OPPORTUNITIES

From a design perspective, it was crucial for these buildings to display their driving purpose: science and sustainability. Expressing the timber framing was paramount and the team took great care to celebrate the natural warmth of the wood elements, both internally and externally. Using moments of transparency to offer views to the buildings’ timber framing, employing expressive exterior wood elements, and prioritizing natural facade finishes, the team created a design expression that speaks to innovation and discovery.

Adjacent to a district park and facing the City’s waterfront, the buildings vary in height, adding a unique expression to Boston’s skyline. The natural edge of the waterfront and the rich landscape defining the park’s public realm are complimented by the timber elements that frame the pedestrian experience along these important edges. Transparency is employed in key areas to celebrate the warmth and natural finish of the timber framing that offers an inviting arrival experience.

The lower building faces the waterfront and is organized with two primary wings. The wing facing the park will offer an amenity rich environment for the entire campus, featuring a variety of active programming to encourage a porous edge at the building’s base. This enlivens the site’s public realm. Along this edge, large-scale angled columns create a dramatic exterior colonnade and support an expressive PV canopy at the building’s roof. This canopy captures a lively roof deck offering striking views to the waterfront and beyond. The other wing will support a collaborative research incubator program meant to support start-up and early stage life sciences companies. These synergistic programs are separated by an awe-inspiring atrium, energized by its active edges. Floating stairs and bridges offer opportunities for spontaneous collaboration and intimate social connection. Both wings offer a transparent face towards the waterfront, allowing the warmth of the “V” shaped timber columns and CLT decking to filter through the glass and bask in natural light. The atrium allows a continuous view through the space to the taller building and by connecting to the PV canopy, visually directs views to the park.

At nine levels, the taller building expresses its timber framing and life sciences use with an orthogonal form; highlighting the wood framing at the building’s base and in transparent openings between its vertically-oriented cladding elements. The lower volume protrudes beyond the upper form to suggest a comfortable scale that contextualizes the lower building and adjacent park. The facade rhythm of the upper building, aligned with the typical lab module, is consistent to serve as a compelling backdrop for the lower volume. Its opaque elements are sculpted into a unique geometry that offers rich detail while framing the wood spandrels. Expressive of its research mission, the highest portion of the building is separated into two volumes allowing the taller mechanical levels to step even further back from the water’s edge.

The interior environment of both buildings promises to be remarkable, as mass timber provides an invaluable biophilic connection to nature. The texture and tone of the wood surfaces calls upon our senses and offers a rich experience scientifically proven to enhance the perception of comfort and calmness. Exposed columns, beams, girders, and CLT decking will provide the final finish throughout most of the interior spaces, complimented by bespoke additions of greenery and other natural finishes. Daylight will flow through the glazing to further highlight the natural wooden grain of the timber elements. The holistic effect results in a warm environment in which scientists can do their best work.

EMBARK ON THE ENDEAVOR

REALIZE THE FUTURE

Having charted a viable map forward for New England’s first all-timber framed laboratory development, our team is passionate about and confident in executing a flagship project for the region.